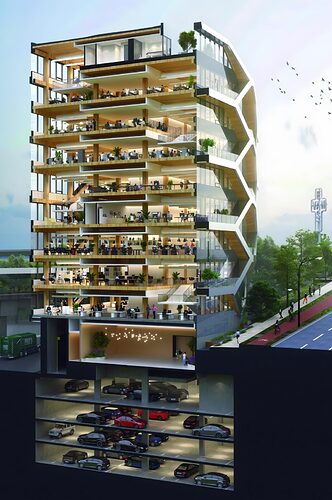

Wood Central speaks to Robert Jackson, the engineer behind the Hive - the world’s most seismically advanced timber building, which will top out later this month. (Photo Credit: Renders from DIALOG)

The world’s most advanced earthquake-resistant timber building is weeks from topping out, with “the Hive”—North America’s largest timber-braced building—rising in downtown Vancouver.

Today, Wood Central spoke to Robert Jackson, Principal at Fast + Epp, one of the world’s leading engineering firms at the forefront of mass timber, who said he was excited to see the building finally “go vertical.”

“They are at level seven right now and will top out later this month at level ten,” Mr Jackson said: “It’s got 105 seismic dampers (which absorb seismic energy and reduce deformations in the structure), and I would say with quiet pride that it is one of the most seismically advanced timber buildings in the world.”

Considered one of the world’s ‘pioneering projects,’ the building features an all-timber system—including glue-laminated timber beams, columns and braces, and cross-laminated timber (CLT) panels—was fabricated by Kalesnikoff from levels 2 to 10. It also includes shear walls and balconies and is a ‘kit-of-parts prefabrication,’ all allowing for rapid on-site construction.

The design features a timber-braced frame (From levels 2 to 10) with four internal cross-laminated timber shearwalls, which were subject to small-scale and full-scale seismic testing. (Image Credit: Renders from DIALOG)

The project uses a ground-breaking lateral system.

Using perforated plate technology — where energy dissipates inside the building’s frame members and shearwalls — the building’s timber-braced frame and cross-laminated timber shearwall system underwent small-scale and full-scale testing at the University of Alberta and the University of Queens. “This provides valuable engineering information to the design community for future tall wood projects,” according to Fast + Epp – which has provided extensive information about the testing.

Working with DIALOG, the project architect, Fast + Epp developed a perimeter timber braced frame system that creates a striking façade and eliminates the need for conventional cast-in-place concrete cores. In addition, the perimeter timber braced frame is paired with four discrete internal cross-laminated timber (CLT) shearwalls.

The four internal cross-laminated timber shearwalls which earlier this year were assembled on site. (Photo Credit: Fast + Epp)

“Having learned that integrated service distribution is key to the successful architectural expression of a mass timber ceiling, Fast + Epp developed a bottom-flush interior girder system using custom steel members,” according to a Fast + Epp case study, adding that “this system creates a ‘flat plate’ ceiling for mechanical and electrical service routing.”

Pushing the boundaries with design

As part of British Columbia’s Mass Timber Demonstration Programme, Mr Jackson said the government has encouraged developers to push the boundaries with timber buildings, “both seismically, but also in bending and compression.” “We’ve been fortunate to be involved in many of these projects, which allow us to do this type of innovation,” he said.

Fast + Epp designed a “flat plate” ceiling system, which helped with mechanical and electrical service routing. (Image Credit: Renders from DIALOG)

According to Naturally Wood, the building is also a “fire-safe tall wood design,” using large timber members specially designed and engineered through extensive testing to withstand the flames and intense fire:

Source: Inside the Hive: World's Most Advanced Seismic Timber Building | Wood Central