Researchers discovered a novel method for converting waste heat into power using sustainable Irish wood products.

According to the University of Limerick experts, this is a sustainable strategy that reduces expenses and environmental impact.

The study shows the effective generation of electricity utilizing “low-grade heat recovered from lignin-derived membranes.”

Low-grade heat

Low-grade heat is defined as thermal energy generated at temperatures below 200 degrees Celsius.

According to the press release, this low-grade category includes a significant amount, roughly 66, of the waste heat generated by various industrial activities.

This temperature range is regarded as less beneficial for typical applications since it is frequently ignored or dissipated without being used productively.

“Low-grade heat comes from various sources like waste heat in industries, heat losses in insulating systems, ocean thermal gradients, biomass fermentation, and solar heat,” said Maurice N Collins, professor of materials science at UL’s School of Engineering.

“Despite its potential, utilizing low-grade thermal energy in energy harvesting applications has been challenging due to the lack of cost-effective technologies,” added Collins.

Various applications of the newly created membrane

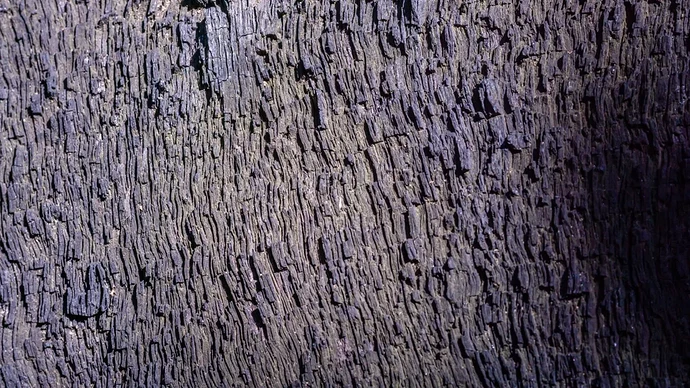

Lignin is a commonly neglected residue of wood in paper and pulp manufacture.

The researchers found that these membranes may transform waste heat into electricity by harnessing the movement of charged atoms (ions) within the material.

“Our research explores the use of ionic thermoelectric membranes made from lignin, an underutilized by-product in the paper and pulp industry, offering a sustainable solution,” said Collins.

This is said to be the first lignin-based membrane for ionic thermoelectric energy harvesting.

The authors highlight that the newly created membrane is “lightweight, easy to synthesize, and biocompatible.”

This innovation could have widespread implications across various industries that produce significant amounts of low-grade heat as a byproduct.

The membrane’s versatility makes it suitable for a wide range of applications, including thermal energy harvesting, temperature sensing, and the creation of biological sensors for health monitoring.

“While there is still room for further development in heat-to-electricity conversion applications, the study demonstrates that abundantly available lignin can successfully contribute to low-grade thermal energy harvesting, especially in scenarios where sustainability and cost-effectiveness are crucial,” said Collins in the press release.

This marks a significant advancement, as earlier research has only used cellulose from raw wood.

The study addresses a critical challenge in the field of energy harvesting, where the cost-effective and sustainable conversion of low-grade heat has been difficult.

The development was made in collaboration with colleagues from the University of Valencia.

This research comes under NXTGENWOOD, which is a project committed to exploring new value-added applications for Irish wood.

It was supported by the Department of Agriculture, Food, and the Marine.

The findings were published in the Journal of Advanced Functional Materials.

Study abstract:

Wood-based ionic conductive membranes have emerged as a new paradigm for low-grade thermal energy harvesting applications due to their unique andtailorable structures. Herein, a lignin-derivedionic conducting membrane with hierarchical aligned channels is synthesized viaa double network crosslinking approach. Their excellent thermal stability andsuperior swelling ratio allow their optimization as low-grade heat recovery technologies. Several vertically aligned nanoscaleconfinements are found in the synthesized membranes, contributing towardenhanced ionic diffusion. Among all the combinations, the membrane comprising69.2 wt.% of lignin and infiltrated with 0.5 m KOH exhibits anexceptional ionic figure of merit (ZTi) of 0.25, relatively higher ionic conductivity(51.5 mS cm‒1), lower thermal conductivity(0.195 W m‒1·K), and a remarkable ionic Seebeck coefficientof 5.71 mV K‒1 under the application of an axialtemperature gradient.