Inherent Deficiencies of Gang Nails and the Engineered Lightweight Wood Truss

Nov. 14, 2022

Photos by Frank Leeb

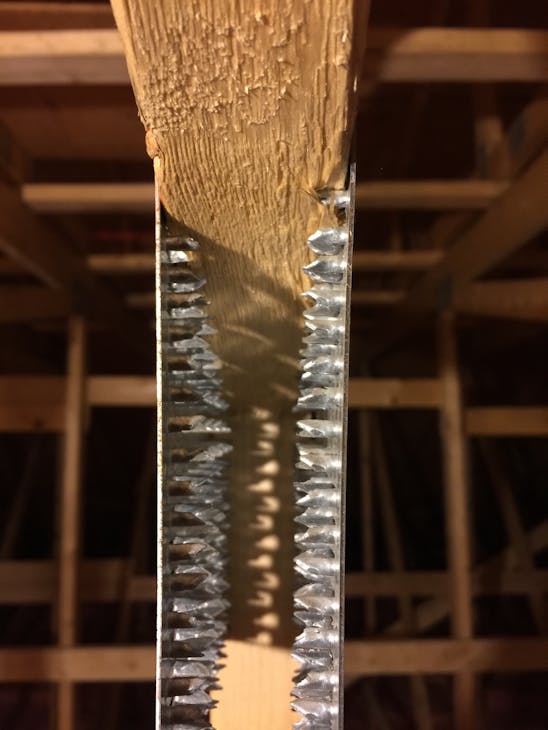

Example of the versatility of the gang nail: holding multiple pieces of a truss system in place instead of costy nails or glue.

The potential dangers of lightweight construction and its inherent deficiencies must be understood by every firefighter and fire officer. From a strategic and tactical standpoint, lightweight construction often dictates and demands fireground strategic and tactical actions that account for early collapse potential. This is particularly true when a fire progresses from a contents-only fire to a structural components fire.

One particular type of lightweight construction of concern is the lightweight engineered wood truss with gang nails, which sometimes is referred to as a gusset plate. This system gained in popularity in the mid-1950s following the invention and patenting of the gang nail connector plate in 1955.

The gang nail connector plate is a sheet of galvanized steel that has stamped triangular pointed prongs that are bent perpendicular to the plate face. This allows all of the prongs to be hammered or pressed simultaneously into the lumber, so the plate forms a bridge across the joint between the wooden web and chord members.

Gang nails are unique in that they don’t require nails or glue to hold the wood triangles together. This saves cost and time. Furthermore, this ability to quickly, easily and inexpensively connect different wooden web members in various truss shapes provided the catalyst of change to the lighter weight, less expensive wood truss construction that prevails today.

Builder benefits, firefighter dangers

Historically, to provide the necessary structural support and to prevent collapse, buildings were designed with a built-in safety factor: increasing the size and mass of the load-bearing structural elements. By contrast, in more modern times, structural engineers who formerly overbuilt a bearing element became capable of determining the exact failure point. More-precise calculations enable builders to use less costly building materials.

Thus, with greater frequency, structures are constructed with smaller and lighter weight engineered building materials instead of the larger, heavier dimensional lumber that’s found in older construction. In short, builders replaced mass with math and now use engineering to eliminate costly overbuilding.

All that said, although engineered building components might provide adequate strength under normal conditions and a benefit and cost saving for the builder, those building components are a potential danger to firefighters when the structural elements are on fire.

Example of a truss loft: engineered lightweight wood truss with gang nails. Firefighters must be aware that a truss can be used to support a floor or roof.

The first LODDs

Engineering and economics are the primary reasons for the design process and popularity of lightweight wood truss systems: The smallest structural members that are necessary to support and carry the anticipated load are used.

Engineered lightweight truss systems most commonly are used in residential private dwellings and garden-style multifamily homes, including such buildings that are in many communities that are 55 years old and newer. However, the systems also are found in commercial structures.

Although the systems were popularized in the 1950s, the fire service wouldn’t see the deadly effect of them until Feb. 28, 1984. This was the day that James Pressnall of the Irving, TX, Fire Department was killed when the roof on a two-story apartment house that was constructed of lightweight wood truss collapsed. According to Chief Vincent Dunn in “Collapse of Burning Buildings: A Guide to Fireground Safety,” Pressnall was the first known firefighter to be killed in a lightweight wood truss collapse.

On Dec. 26, 1992, two firefighters were killed when a lightweight wood truss roof collapsed while they battled an arson fire in a church in Memphis, TN. The collapse occurred only seven minutes after the arrival of firefighters. On Feb. 14, 2000, two firefighters were killed battling an early morning arson fire in a McDonald’s restaurant in Houston when the lightweight wood truss roof collapsed. Gang nails held the truss roof together in both buildings.

Trusses often are manufactured off site. Sometimes, gang nails become lose during delivery and are hammered back in during construction.

Why they fail

In a structure that’s constructed with lightweight materials, when fire extends from the building’s contents to its structural components, collapse might occur within 5–10 minutes, and it might occur suddenly and with few or no warning signs. Collapse always is the primary consideration in buildings that are constructed out of lightweight materials.

Our experience shows that structural collapses occurred in buildings where the magnitude of fire was relatively small. Therefore, quickly positioning the first hoseline to control a contents fire that hasn’t extended to the structural components is of paramount importance.

Lightweight construction often provides for the creation of large rooms. Areas that are unsupported by columns that have spans that are greater than 25 feet generally are an indication that lightweight construction is present. The collapse potential in a “wide open” room of this type is greater than it is in a compartmented area that has interior walls.

In the absence of increased mass, the strength of a lightweight system is obtained through the interconnection of multiple structural components, which provide support in compression and tension. Furthermore, the decrease in size and mass of the individual structural components affects the stability of all of the other structural components; if one fails, the others might fail, too.

This type of support system typically is made up of 2 x 3-inch or 2 x 4-inch wooden web and chord members that are connected with sheet metal gang nails. Because these connections only penetrate a quarter- or a half-inch into the wooden truss member, the gang nails become the weakest point of the system. When exposed to fire and/or high heat, failure at the point of connection should be expected before failure of the structural wood components. This is because the gang nails might loosen and fail, which causes the entire span of that particular truss section to fail. In any building construction, the critical area that’s subject to failure as a result of fire is the point of connection.

The high surface-to-mass ratio of wood trusses provides an abundant fuel source, and the air supply that’s in the concealed truss void allows for rapid horizontal extension. Because of the open-web characteristic of the truss system, fire that enters a ceiling (truss loft) or roof space (cockloft/attic) likely will affect all truss supports that are on that level, which creates the potential for a large-scale collapse of the area that’s supported by the affected trusses.

The design flaw of the gang nail from the firefighter’s standpoint is the limited penetration (a quarter- to a half-inch) into the wood, which leads to early failure during fire conditions.

Concealed spaces are created when both the top and bottom of lightweight wood truss systems are covered with wooden sheathing, gypsum wallboard or other materials that enclose the area from roof to ceiling. These concealed spaces are known as truss voids or truss lofts. Joist and rafter roof systems also have these concealed spaces.

The 5–10-minute time frame that it takes a lightweight wood truss to collapse in a fire often is about the same time frame that it takes firefighters to get to the scene.

As stated in the U.S. Fire Administration’s technical report of the Dec. 26, 1992, Memphis collapse, “The significant factors in this incident include the short time that a lightweight wood truss roof structure can be expected to maintain its structural integrity when involved in a fire and the lack of warning indicators of pending collapse.”

It’s critical that any member who becomes aware of lightweight construction notify the incident commander immediately. It might be necessary to remove members or to suspend interior operations until further assessment of structural stability and collapse potential can be made.

Know in advance

Trusses come in many sizes, shapes and designs. It’s important that firefighters are able to identify them and the dangers that they might pose.

Trusses generally consist of wood but are often constructed with metals, too. Different material might act differently under fire conditions, but all are subject to failure.

Without question, the most important factor to a safe and successful operation at these types of buildings is the identification of the presence of lightweight construction. Ideally, the identification of an engineered lightweight wood-constructed building is made before a fire alarm is received.

Since 1984, more than a dozen firefighters lost their life in these lightweight structures. Know your building and operate accordingly. Once a fire changes from a contents-only fire to a structural fire, it’s only a short amount of time before a collapse occurs.