The Lumber Shortage Sucks, But Lab-Grown Wood Could Save Your Next DIY Project

New research could lead to customizable timber-like products for the building industry.

BY TIM NEWCOMB

JUN 9, 2022

MIRAGECGETTY IMAGES

- With deforestation and natural disasters decimating timber stands, lab-grown options offer hope for the future of building.

- MIT researchers can customize properties of plant materials to tweak them for different uses.

- The lab-based process can reduce time and waste from the process.

As wood grows more scarce across the globe—think deforestation and forest-devastating wildfires—researchers at the Massachusetts Institute of Technology have a plan: to grow wood-like timber in a lab. And the MIT effort comes fully customizable, taking plant material and modifying it to the needs of DIYers just like you.

In the MIT project, researchers crafted wood-like plant material in the lab, adjusting chemicals in the growth process to precisely control the physical and mechanical properties, such as stiffness and density. That makes the end result potentially viable as a wood substitute in a variety of construction projects.

“This work demonstrates the power that a technology at the interface between engineering and biology can bring to bear on an environmental challenge,” Jeffrey Borenstein, a biomedical engineer and group leader at the Charles Stark Draper Laboratory, says in a May 25 news release. He adds that the work is “leveraging advances originally developed for health care applications.”

Deforestation continues to increase, and a variety of factors—from wildfires in the Pacific Northwest and British Columbia, to delayed lumber shipments and a boom in home building—have helped spur the price of lumber to over $1,000 per thousand board feet on multiple occasions in the last two years. Finding a sustainable solution has become paramount.

In the MIT research, published earlier this year in the journal Materials Today, scientists isolated cells from the leaves of Zinnia elegans plants and then cultured the cells in a liquid medium for two days. From there, they moved to a gel-based medium with nutrients and hormones. By adjusting the hormone levels early in the process, researchers could alter the plant cells, even though they haven’t quite yetgraduated to cultivating full-blown timber replacements.

“In the human body, you have hormones that determine how your cells develop and how certain traits emerge,” Ashley Beckwith, lead author of the new study, says in the MIT news release. “In the same way, by changing the hormone concentrations in the nutrient broth, the plant cells respond differently. Just by manipulating these tiny chemical quantities, we can elicit pretty dramatic changes in terms of the physical outcomes.”

The team took advantage of the adaptability of plant cells in a way that calls to mind how stem cells change form to fulfill specific functions. First, researchers extrude the plant’s cells and place them into a petri dish for three months of incubated darkness. Then comes a dehydration step before completion. The researchers say they were able to grow plant material with a stiffness similar to natural woods by using higher hormone levels to create additional lignification. The result was a more rigid and woody structure.

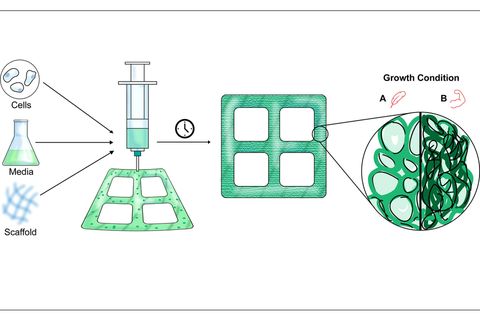

In an effort to provide an environmentally friendly and low-waste alternative, researchers at MIT have pioneered a tunable technique to generate wood-like plant material in a lab.

IMAGE: COURTESY OF THE RESEARCHERS/MIT

Zinnia plants may be the start, but researchers want to start exploring using additional species, such as commercially important tree species, in their process.

The 3D-bioprinting process also allows the growth of the material in custom shapes and sizes. “The idea is that you can grow these plant materials in exactly the shape that you need, so you don’t need to do any subtractive manufacturing after the fact, which reduces the amount of energy and waste,” says Beckwith. “There is a lot of potential to expand this and grow three-dimensional structures.”

Luis Fernando Velasquez-Garcia, principal scientist in MIT’s Microsystems Technology Laboratories, says customization provides a benefit. “I think the real opportunity here is to be optimal with what you use and how you use it,” he says in the news release. “If you want to create an object that is going to serve some purpose, there are mechanical expectations to consider.”

The researchers also hope to spark interest in others to join the effort. It could help solve major wood-shortage issues while giving us a new lab-based home for some of the most important commercial forests.

TIM NEWCOMBTim Newcomb is a journalist based in the Pacific Northwest.