Anthony Cuthbertson

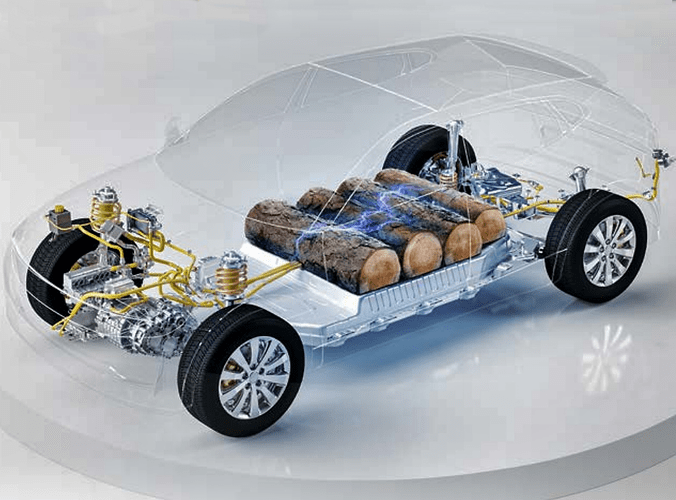

A new type of wood-based battery has the potential to significantly decrease the charge time of electric cars while dramatically improving their environmental sustainability, its creators claim.

The breakthrough centres on a material called lignin, an organic polymer that makes up roughly 30 per cent of all trees.

Researchers at Swedish-Finnish firm Stora Enso, Europe’s largest forestry company, discovered that lignin could be transformed from an unwanted by-product of its paper mill business into a bio-based alternative to graphite anodes found in lithium-ion batteries

By turning lignin into a hard carbon, the researchers were able to create a low-cost, ultra-efficient anode that they describe as “a revolution” in battery technology.

“Cost wise we will be very competitive but it is the performance that is the most exciting,” Lauri Lehtonen, head of Lignode at Stora Enso, told The Independent.

“In terms of high charge rates, hard carbons can take you into places that graphite cannot. Graphites limits are somewhere around 40-50 minutes, which you can stoke with a very expensive silicon to reach 20 minutes. [Lignin-based anodes] can achieve charge times of eight minutes.”

Fossil-based graphite is currently the predominant anode material used in nearly all lithium-ion batteries, which are used in everything from smartphones and cameras, to electric vehicles and drones.

This is despite limitations when it comes to high capacity charging, as well as the environmental damage caused in its mining and production.

The growing and production of lignin anodes is by contrast carbon negative, while its amorphous structure means ions can enter from all directions and move more easily and rapidly than crystalline graphite, allowing for faster charge and discharge rates.

Stora Enso plans to commercialise the technology on a massive scale. With the paper industry in decline, the company is currently shifting its focus towards developing sustainable products that can replace fossil-based materials.

Lignin is the second most abundant biosource in the world behind cellulose, with a potential global supply of around 50 million tons. Currently only around 2 per cent is actually used for industry, with the rest just burned for energy. A study published earlier this year by researchers in Korea detailed how lignin-based materials could also be applied to other components in rechargeable batteries, including the binder, separator, eletrolyte and cathode.