WOODEN SKYSCRAPERS ARE ON THE RISE

Engineered ‘mass timber’ takes the place of concrete and steel By Eric Niiler

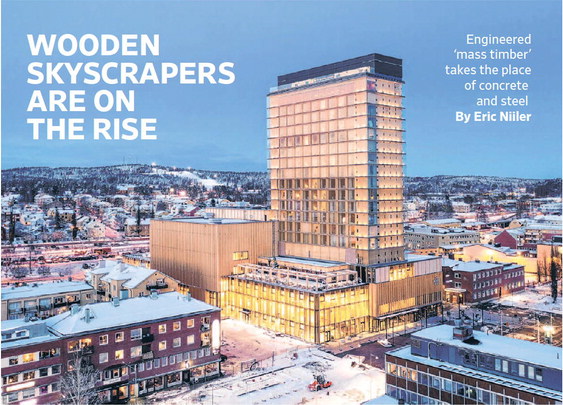

Guests at a new 20-story hotel and cultural center in Skellefteå, a former gold-mining community in northeastern Sweden, don’t have to step outside to feel immersed in the natural world. The floors, ceilings and support beams of the building— which also houses a museum and other facilities—are made almost entirely of spruce and pine harvested from nearby woodlands.

“When you come inside, the smell of the timber is almost like you enter a forest,” Robert Schmitz, a partner at an architectural firm in Stockholm and one of the building’s lead architects, says of the Sara Cultural Centre and Wood Hotel. “This is a really small city, and timber is something that everyone in this community has a connection to. They understand the material.”

The 323,000-square-foot complex is part of an emerging trend as architects, developers and builders turn to so-called mass timber, wood that is glued and pressed in special ways to make it similar in strength to concrete and steel and thus capable of replacing those building materials even for skyscrapers and other massive edifices.

Advocates of mass-timber construction maintain that it can be more environmentally friendly than conventional construction. The carbon footprint of a building constructed with sustainably harvested mass timber, which is made from trees that are selectively cut rather than clear-cut, can be half that of a similar building made of concrete and steel, according to an assessment of mass timber construction published recently in the journal Sustainability.

“If you look at the carbon impact of harvesting trees and turning them into buildings, it gives you a much better number than you get from concrete or steel,” says Stephen Shaler, a professor of sustainable materials and technology at the University of Maine. “As long as you have sustainably managed forests—and we have that capacity—it is a clear winner on the carbon footprint.”

The number of multistory mass-timber buildings being built in the U.S. rose 50% between July 2020 and December 2021 to more than 1,300 structures, according to the wood trade group WoodWorks. Among the projects are an eight-story office building in Charlottesville, Va., a new Google five-story office building set to open in August in Sunnyvale, Calif., and a 25-story residential-retail complex rising in Milwaukee.

Even more ambitious projects may appear: A Japanese timber company has proposed a 70-story wood building for Tokyo, while a U.K.based architectural firm has plans for an 80-story skyscraper in London.

To meet the demand for mass timber, 18 manufacturing plants have been built in the U.S. and Canada since 2014, according to the U.S. Forest Service. The global market for mass timber was estimated at $956 million in 2020 and is expected to grow at an annual rate of 13.6% from 2021 to 2028, according to a December 2021 report by Grand View Research.

In addition to potential en- vironmental benefits, construction experts say mass-timber buildings can cost less than concrete-and-steel structures— especially if they’re sited near a manufacturing plant where pieces of the building are cut to order. With mass timber, for example, builders don’t have to pour concrete and wait for it to set. Mr. Schmitz and the team behind the Sara Cultural Centre say they saved a year in construction and labor costs as the wood panels and beams were made at a nearby plant.

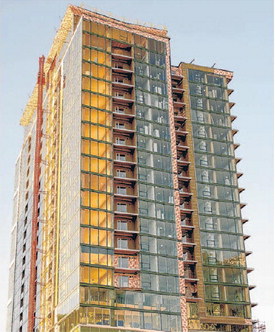

Using mass timber cut the timeline for the Milwaukee complex, called Ascent, by about four months, says Tim Gokhman, managing director of the Milwaukee-based New Land Enterprises and the project’s manager. Because wood is lighter, only 100 support piles had to be driven into the site’s soft soil rather than the 200 that would have been needed for a similar concrete-and-steel building. And whereas pouring concrete floors might require 30 to 40 workers, he said, only 10 workers were needed to install the cross-laminated timber, or CLT, panels for each floor.

CLT is made by laying down and gluing together multiple wooden pieces oriented at 90-degree angles to one another and is commonly used for floors and walls. Another key type of mass timber, called glulam for glue-laminated timber, is commonly used for support beams.

“Each piece of wood is measured and has a designated place,” Mr. Gokhman says. “So as the building is built, you’re literally updating its progress in a digital world.”

Some point to limitations of mass timber, sayingthat buildings made with both conventional and

![]()

![]()

![]()

mass-timber construction can have advantages over those made solely of wood or solely of steel and concrete.

“In a tall building, you really do want the base of it to be concrete, and as you go up in the building it gets lighter, and makes more use of wood,” says University of Oregon architecture professor Judith Sheine, who has designed buildings using both mass timber and concrete and steel. And conventional construction might be better in coastal areas, she says, adding, “If you’re in a flood zone, the base should still be concrete because getting wood wet is not that great.”

Some fear the mass-timber trend could spur timber companies to cut down old-growth forests that contain large amounts of carbon rather than selectively harvesting younger forests. They argue that calculations of the carbon footprints of mass-timber buildings must include roots, branches and other parts of trees that are often burned as well as the fossil fuels consumed to cut down the trees, fabricate the wood products and transport them.

“We’re not going to log our way out of the climate crisis,” says Jason Grant, manager of corporate engagement, forests, for the World Wildlife Foundation in San Francisco.

Seismic testing of a 10-story tall wooden building scheduled to take place in California this fall could give a boost to mass timber. “We need to find a way to make these buildings earthquake-resistant, since it’s a new building type, and nobody’s ever done this before,” says Shiling Pei, associate professor of civil and environmental engineering at the Colorado School of Mines and the project leader for the shake test.

To minimize the risk of fire, builders and architects are incorporating precautions into mass-timber buildings, says David Barber, a Washington, D.C.-based fire safety engineer with the multinational design, engineering and architectural firm Arup. He points to covering CLT wall and floor panels in taller mass timber buildings with fire-rated drywall, for example, and checking the fire rating for connection points between the timber panels as well as the glue connecting the panels and laminated timber.

“We want to make sure that the buildings are done in very conservative ways, so they are being designed to a very high level of safety,” says Mr. Barber, who has worked on the Ascent building in Milwaukee and the eight-story Apex building in Charlottesville.

18 mass-timber, manufacturing plants have been built in the U.S. and Canada since 2014, according to the U. S. Forest Service.

A 25-story complex in Milwaukee, called Ascent, is being built with mass timber.

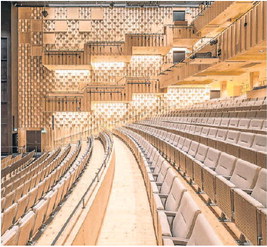

Top, the Sara Cultural Centre and Wood Hotel in Sweden is largely constructed of locally harvested spruce and pine. Above, a theater inside the complex.